The entire process is isolated from the ambient environment. This extruder melts the material and selectively deposits it onto the build platform through a nozzle attached at the end of it. The filament material enters the extruder where it is heated to a temperature of about 320˚C. A typical FDM machine consists of an extrusion-nozzle assembly, a build platform, and a material in the form of a filament. Stratasys patented the process in the year 1989. Stratasys’ Industrial grade FDM 3D Printerįused Deposition Modeling (FDM) is a proprietary technology by Stratasys, Ltd. But despite being similar, they are different.

Here’s a short answer to your question: They are similar. So that means they are one and the same, right? No. However, if durability and end-use function in extreme conditions is important to you, FDM is your best bet.Doesn’t FDM and FFF cater to a similar technology? Yes. If you are looking for high-resolution, ultra-fine parts, PolyJet is a great option. If your part is larger than the FDM dimensions above, the design file can be split into multiple pieces, with each piece built on a separate machine and then bonded together, giving it the strength and functionality as if it was a single part.īoth technologies have their strengths and limitations it is ultimately up to how the part will be used when determining what technology to choose. However, FDM technology allows you to build parts as large as you need them to be. and FDM parts can be built up to 36 x 24 x 36 in. Both PolyJet and FDM offer similar dimensions for the maximum part size from a single system: PolyJet parts can be built up to 39.3 x 31.4 x 19.6 in. The size of your part also needs to be considered when choosing a technology.

The FDM process will produce layer lines on parts, but these lines usually do not affect a part’s strength or functionality. If this is the case, PolyJet’s use of multiple materials and attention to detail is often a good option.Īnd while FDM does not offer the detail PolyJet does, it can still produce parts with complex geometries and intricate components. For concept modeling and some prototypes, the surface finish and aesthetics can be crucial. The importance of how a part looks when completed largely depends on how the part will be used. When printing in FDM, you have the ability to choose from different thermoplastics that can withstand a wide variety of elements, from extreme temperatures to exposure to certain chemicals. PolyJet can also print parts with variety of flexibilities, from rubber-like parts to those that have a more rigid feel. If attention to detail is a crucial component of your part, PolyJet will be able to produce the small features and fine textures you need. It is also important to consider what material is needed to satisfy your part’s application. If fit and function are critical to your part, FDM may be the best choice. While PolyJet makes its name with exceptional detail, FDM hangs its hat on the ability to produce durable parts that are ready for end-use applications. How will your part be used? PolyJet’s ability to create parts with great intricacy makes it a great choice for concept models. There are a few key things to consider when choosing the right technology:

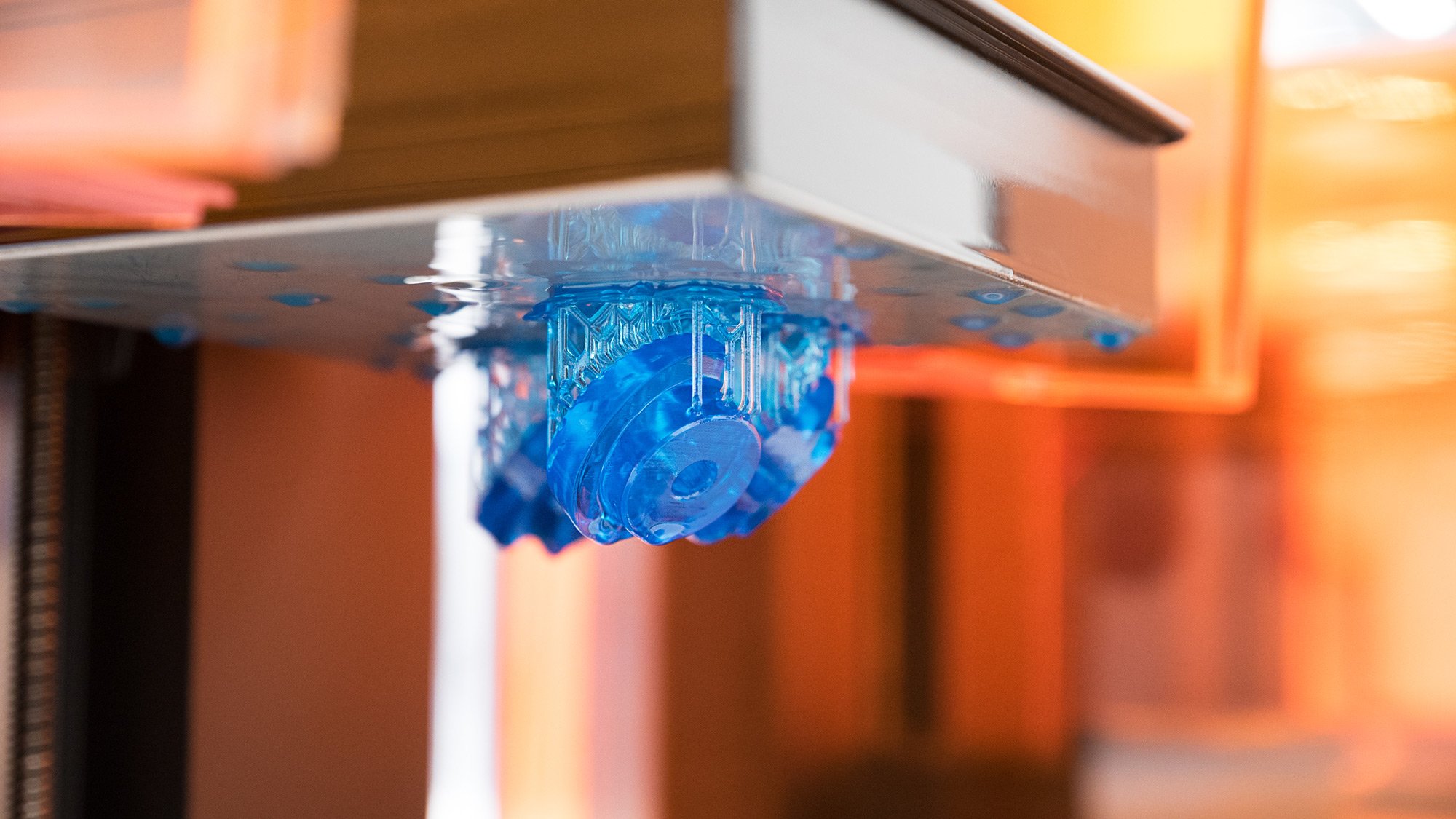

Since the process and materials are different, the characteristics of parts each produces will be different, too. After a thin layer is created, the process repeats itself by jetting additional layers until the part is fully formed. The PolyJet process is different in that a carriage jets photopolymers onto the work space, which are then cured by a UV light. The machine head repeats the extruding and melting, layer by layer, until the part is complete. Once extruded into a bead, the material is immediately set in the high temperatures of the machine and layered on a platform. FDM uses a thermoplastic filament that is melted down and extruded from a print head.

0 kommentar(er)

0 kommentar(er)